Development and characterisation of additively manufactured patient-specific dental implants

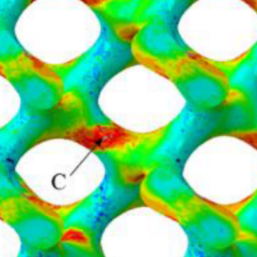

The hypothesis is pursued that individualised, graded dental implants with improved biomechanical load and tissue integration can be developed through laser-based powder bed fusion. For this purpose, complex model systems (in silico and in vitro) have to be set up that permit the assessment of the biomechanical load on dental implants, as well as cell and biofilm adhesion. First of all, an FE model for graded dental implants is being developed. This model allows the gradation to be adjusted specifically for each patient, in order to permit optimal biomechanical loading of the implant and the peri implant bone. CT/DVT data from selected patients with different bone types are segmented and transferred to a CAD model for the design of patient-specific implants. The FEM is used to optimise the topology of the implant with regard to the local graded material properties. Different load scenarios are addressed - such as force level and direction, occlusal contact situation, cusp inclination, antagonists and the type of superstructure. The FE analyses help to reduce the number of test samples and the complexity of the subsequent in vitro and in vivo experiments and thus also support the 3R concept. For the long-term prognosis of medical implants and to achieve permanent osseointegration, both topology and surface properties are important. We will analyse how tissue integration is influenced by various physical and chemical functionalisations of the surface. The development of patient-specific additively manufactured and surface-functionalised implants and the characterisation of their biomechanical and biological properties is only possible if we develop in vitro model systems. For mechanical characterisation, the fatigue behaviour of the additively manufactured implants must be examined. Moreover, it must be investigated whether standardised methods for the qualification of mechanical products (DIN 14801) are suitable for the patient-specific solutions. Parameter limits are worked out in the design space, which lead to predictions for clinical use. To characterise the interactions between implants, human tissues and bacterial biofilms, the graded and surface-functionalised implants are first examined with regard to the adhesion of human cells and bacterial mono- and multispecies biofilms. In addition, a 3D model is being further developed that permits simultaneous analysis of the complex interactions between these three components.