Profile

Aim of the research unit will be the development and validation of an integrated solution for the manufacturing, characterization and simulation-based design of additively manufactured implants in maxillofacial surgery, taking into account physiological conditions of the individual bone situation. Therefore, a holistic qualification approach, as well as an interdisciplinary consideration of materials science and engineering, medical engineering and numeric simulation, is required. Based on this, novel and mechanism-based in vitro and in vivo testing methods, including multi-scale simulation and modeling methods (in silico), are implemented by the interdisciplinary consortium in order to describe the mechanical, biological and corrosive processes and their interactions. Due to the present diversity and complexity of the envisaged research topic, interdisciplinary processing by young scientists, supervised by proven researchers, is mandatory. The complexity of the pursued scientific issues will be increased stepwise. Within the first funding period (FP-1: 1st to 4th year) the mechanical-biological behavior of permanent implants made of titanium will be characterized. Supplementary, the effect of corrosion mechanisms on the mechanical-biological behavior of bioresorbable implants made of magnesium will be faced in the second funding period (FP-2: 5th to 8th year).

In summary, the following overall objectives can be defined:

- Patient-individualized implant design by considering specific bone structures and possible bone defects (e.g. prevention of bone augmentation)

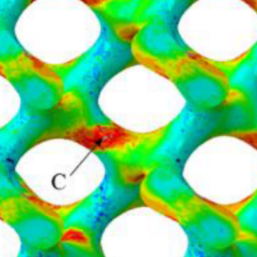

- Minimization of stress-shielding within implant-bone interface through local adjustment of stiffness by using lattice structures for a successful tissue integration

- Characterization of the influence of lattice structuring on quantities such as microstructure, defects formation and topography, and the correlation with the corresponding property profile

- Modification of surface morphology and properties through surface treatment (e.g. sandblasting) and coating (e.g. PEM coatings) in order to stimulate tissue integration

- Time- and resource-efficient simulation and modeling of the mechanical, biological and corrosive property profile via multi-scale approaches by linking multiple levels of scalability with the aid of artificial neuronal networks

- Development of a time- and resource-efficient experimental and simulation-based characterization methodology to increase the quality, consequently also the long-term survival rate and to accelerate the development and qualification period for future implants

March 2025: Impressions and current research topics from the FOR 5250

Please confirm video activation.

After activation, cookies will be set and data is sent to YouTube (Google).

To the Google Privacy Policy

April 2024: Insights into the FOR 5250

Please confirm video activation.

After activation, cookies will be set and data is sent to YouTube (Google).

To the Google Privacy Policy

April 2022: The FOR 5250 presents itself

Please confirm video activation.

After activation, cookies will be set and data is sent to YouTube (Google).

To the Google Privacy Policy