In-silico design of implants based on a multi-scale approach

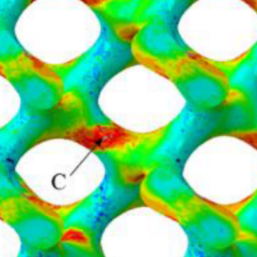

Optimized permanent implants are to be developed in the research unit. Additive manufacturing results in a great degree of freedom in terms of geometric design. As a result, the lattice structure in the implant can be adjusted in a targeted manner in order to optimally adapt the implant to the surrounding bone. Funding period 1 focuses on permanent implants. In particular, the functionality of the implant must be guaranteed over a long period of loading. In this SP-7, a cross-scale model is developed that takes into account the influence of damage effects on the microscale, of notch effects of the grid structures on the mesoscale, and stress shielding on the macroscale. To this end, a new type of homogenization approach is being introduced that allows the scales to be linked in a time-efficient manner using machine learning. In addition, the thermodynamic topology optimization is further developed in order to determine the optimal digital implant across all scales, taking into account process-related damage and stress-induced fatigue effects. In order to find the optimum between lattice structure and functionality, an efficient multi-scale algorithm is developed. The fatigue behavior under stress at high (HCF, High Cycle Fatigue) and very high number of load cycles (VHCF, Very High Cycle Fatigue) is modeled on the microscale. It is assumed that the failure occurs mainly at the grain boundaries. The investigation of the influence of the lattice structure on the stress-strain relationship takes place on the mesoscale. The optimization of the implant in terms of fatigue strength, load-bearing capacity, and morphology is ultimately carried out on the macro scale. The data transfer between the individual scales will be realized based on specially developed artificial neural networks.